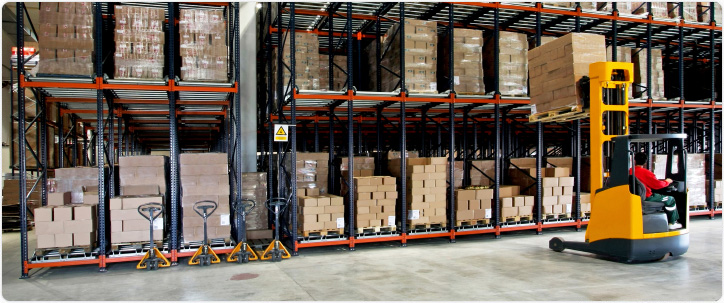

If you’re in need of goods transport from one warehouse to another, then you require industrial material handling. These vehicles or devices can range from containment storages that houses entire shelves of merchandise to the forklifts used to carry them from factory to warehouse to stores nationwide. Every year, there’s a new improvement or innovation waiting to be implemented on the age-old necessity of industrial material handling. Every new system or invention is introduced for the sake of increasing safety and efficiency.

The Latest in a Long Line of Industrial Material Handling Equipment

A quality piece of industrial material handling equipment should be able to improve the efficiency of your work while increasing the amount of safety of the operators of the machine themselves. It’s a twofold process that kills two birds with one stone. You get to make sure that the wheel keeps turning and the cycle continues, but in a faster pace, while the wellbeing of your workers and your investment is altogether safeguarded, thus resulting in increased profits on your part. The real enemies of those in the industrial material handling business is malfunctions, safety hazards (since heavy lifting machinery is always prone to danger in light of all the weight involved), and similar concerns.

The last thing you want to happen is to have an inexperienced or DUI operator who’s operating all this machinery without regard for their efficiency or the safety of everyone concerned, including himself. The equipment can also break down at inopportune times whether it’s because of wear-and-tear or also because of the inherent dangers of overloading when you’re facing deadlines and whatnot. Therefore, you should make sure that both the machines and the people tasked to run them are handled properly. Your employees should follow standard operating procedure, while the equipment should be fixed and regularly maintained.

What to Look for When It Comes to Industrial Material Handling Equipment

The best industrial material handling equipment should find safe yet dependable ways to deliver whatever it’s tasked to deliver or store whatever it’s tasked to store efficiently. Efficiency is all about paying less and getting more, or at least some sort of balance between investment and results. If it’s industrial material handling on the storage side of the equation, you should be assured that you’re taking up less space so that you’ll pay less real estate for safekeeping of all sorts of products, especially harmful industrial chemicals. You should be savvy when upgrading your equipment; pay too much, and you’ll go bankrupt.

Pay too little, and you’ll pay for the rest of it in one way or another. Your employee safety should also be at the forefront of your concern, because if anyone gets injured or dies on the job, you will face quite a lot of financial and legal repercussions that could destroy your company outright if you’re not careful. If you’re going to do a job, then it should be done right the first time every time. Sure, there should be leeway when it comes to mistakes and mishaps, but it shouldn’t come at double-digit percentages. Otherwise, you’re left with either faulty equipment or undependable employees.

Supply Stores, Labeling, and Every Other Industrial Material Handling Job Aside from Forklifts

Aside from forklifts, there’s a lot more to industrial material handling than simply moving barrels, crates, shipments, and cargos from one place to another through land, sea, and air. It includes warehouse considerations, supply stores, labeling and marking bins, intensive training to the people hired for the job to ensure superior storage, handling, and distribution of either the finished product or the component ingredients of each product. This isn’t a simple courier service. It is “industrial”-level handling of materials, which means everything is heavy duty.

For example, this entails figuring out how to operate mechanical equipment, which vehicle or tool should be used to lift things off the shelf, what the parts you have on hand are and what they should be used for, and proper labeling of every last bin and crate so everyone has a good idea what’s in the inventory even before checking out the merchandise. Robotic advances has made things a lot easier than before, but with these advancements come a whole new set of challenges, like manning the computer and making sure the programming is bug-free.

William Henry owns a small hardware store in New Mexico. He is an avid customer of medleycompany.com and only trusts them when it comes to industrial material handling supplies.