Where would we be without PVC? Well, currently I would probably be receiving multiple electric shocks because my computer cables probably wouldn’t have such an excellent insulator, I’d also in all likelihood be on the phone to a plumber because some of the metal pipes in my plumbing would need to be replaced. So just how did this amazing type of plastic get its start in life? What do we use it for and what is it best at? Lets find out…

Where would we be without PVC? Well, currently I would probably be receiving multiple electric shocks because my computer cables probably wouldn’t have such an excellent insulator, I’d also in all likelihood be on the phone to a plumber because some of the metal pipes in my plumbing would need to be replaced. So just how did this amazing type of plastic get its start in life? What do we use it for and what is it best at? Lets find out…

False Starts and Fresh Beginnings

Polyvinyl Chloride is one of the few substances that was not only discovered or invented once, but twice – the first time was by French physicist and chemist Henri Victor Regnault in 1835, and then again in 1872 by the German chemist Eugen Baumann. Though both these gentleman knew that they had discovered something neither of them were quite sure how to use this new substance. Although the German born chemist Friedrich Klatte invented a new way for the polymerisation of Vinyl chloride to take place in 1913, it wasn’t until Waldo Semon – an industrial scientist working as a researcher- tried boiling it at a high temperature in 1926 that people were really able to start thinking up ways to use this strange new material.

The First Foray into Consumerism

Though Waldo knew there was a lot that could be done with this new Polyvinyl Chloride substance he wasn’t too sure just what they could apply it to to begin with. Oddly enough they started by making shoe heels and golf balls out of PVC but the first big consumer product happened in the 1950s and 60s – the record. The fact that PVC is easily mass produced and moulded meant that multiple copies could be made easily, great news for the music lovers as it was found that songs recorded well onto Polyvinyl Chloride, or “Vinyl”.

Branching Out

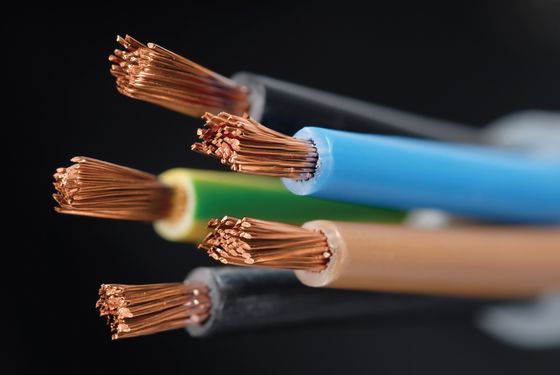

People soon began to realise that PVC could be used in most applications and experimentation began with stabilisers, impact modifiers and plasticisers. This opened the door to whole new possibilities from weather sealed window and door frames to electrical wire coverings and sewage or water pipes – the biological and chemical resistance in PVC meant that it could be used where other materials would corrode too quickly or easily. This fame came with a price and soon PVC was forced to under go more changes in order to stand up to building codes ( for example Chlorinated Polyvinyl Chloride or CPVC is used to carry drinking water in most parts of the united states), or to add to the aesthetic appeal of houses This created Unplasticised polyvinyl chloride (uPVC) for construction and mean that people could add realistic looking wooden framing to doors, windows and for cladding on their houses.

Not content in taking on Construction and Sanitation PVC also became used in materials for clothing, tents and… bouncy castles. Due to the fact that it could be created to be very soft but also durable and waterproof it wasn’t long before it was used in coats, shows and for clothing in certain jobs where waterproof gear was required.