Packaging waste has become a major issue for consumers. That means it needs to be a major issue for businesses. In practical terms, this means reducing the amount of packaging used and prioritising reusable packaging and recyclable materials.

The problem of packaging waste

There is a strong link between packaging and branding. To a certain extent, therefore, packaging is an extension of marketing. Up until fairly recently, many companies took this to mean that using excessive packaging was fine as long as it promoted the brand. In fact, excessive packaging was almost expected on premium and gift products.

Now, however, consumers have become much more aware of the sustainability issues this creates. Many also understand that excess packaging creates excess costs for them too. Firstly, there is the cost of the packaging itself (plus the added transport costs). Then there is the cost of disposing of it.

The latter is currently likely to be absorbed into council tax. This does, however, mean that funds have to be dedicated to waste management instead of other purposes. It’s also very possible that local councils will start making direct charges for waste pick-up.

For example, they may charge for landfill waste but not recycling. Alternatively, they may give residents a certain allowance for free but charge above that. If they do, they will probably charge more for landfill waste than recycling. Whatever approach they take, however, there will be a link between use and cost.

The business benefits of reducing packaging waste

There are two key business benefits of reducing packaging waste. The first is that it improves customer satisfaction. The second is that it often helps to reduce costs for the business.

This latter point is likely to become more and more evident over the course of the future. It seems very likely that governments are going to take measures to incentivise businesses to package more sustainably.

They might even force businesses to take back any waste they produce and arrange for its disposal (at the business’ expense). This approach would probably be easier to implement in the business-to-business sector than in the business-to-consumer sector. With that said, there are already schemes of this nature running in the B2C sector. They are therefore clearly not impossible.

How your business can reduce packaging waste

No matter what type of business you run, you’re probably using some form of packaging. That means you need to commit to a constant process of improvement.

In other words, you should always be looking for ways to use less packaging. You should also be trying to make the packaging you do need easier to reuse and/or recycle.

Here are some specific points to consider.

Try to buy products with less packaging

If you’re selling products that have been made elsewhere they will have to come in some form of packaging. In some cases, this may be completely removed before the item is sold. In other cases, however, only a part of it will be removed. The rest will stay on the item until it reaches its end destination.

In either case, you can use your purchasing power to reward suppliers who do their best to minimise packaging waste. What’s more, you can make it clear to them and their competitors that this was a factor in your purchasing decision. If you’re tied to a single supplier then make it clear that you will look for alternatives as soon as you are able.

Create your own packaging

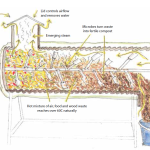

In some cases, a business may benefit from creating their own packaging. Depending on the product, this can actually be a more cost-effective method of creating something unique for your brand, but that also contributes to less waste.

One way to consider could be vacuum formed packaging, a process that literally forms itself to the desired shape, resulting in a final design that fits your product like a glove. This particular method has been used for various sectors including medical and food.

Try to have customers provide their own packaging

Right now, this only really works for real-world stores but the concept is certainly growing in that environment. Probably the most obvious example of this is that it’s much less common for businesses to give out free plastic bags. Other mainstream examples are the reduced use of disposable cups and cutlery in the food and beverage sector.

There is, however, still a lot of room for improvement in this area. For example, many groceries come pre-wrapped, often in plastic. Sometimes, the wrapping is necessary for protection (e.g. with soft fruits and berries). Even so, it does not have to be single-use plastic. Most of the time, however, it’s purely for convenience.

Pre-wrapping products makes it easy for shops to sell consistent quantities of items. It also means that customers can immediately see how much they will pay. Likewise, the cashier (or customer) can scan the item quickly at the till. Unfortunately, the price to pay for this convenience is a lack of flexibility in sizes/quantities and a lot of unnecessary packaging.

Up until fairly recently, it was standard for customers to bring their own packaging. Where this was not practical (or they forgot), it was standard for them to pack items into paper bags themselves. These could then be pre-weighed and/or weighed at the till. Shoppers of all ages are showing themselves increasingly willing to go back to this approach. It could therefore be well worth testing.

Size packaging to fit products

One frequent complaint about ecommerce businesses is that the size of the outer packaging is often totally out of proportion to the size of the item. There appear to be two main reasons for this. The first is that businesses include more protective packaging than is necessary. The second is that it can make for speedier packing.

With smaller businesses, it’s more likely to be the former. It’s therefore sensible to think about how much protection items really need. If you’re sending a mixture of fragile and non-fragile items, try creating mini-packages for the fragile items. This will probably be much more economical than filling an entire box with padding.

Switch to paper instead of plastic

In the UK, the big selling point of plastic is that it’s waterproof. Again, however, it’s questionable how much waterproofing parcels actually need. They are not left outside uncovered for hours. Quite the opposite, most parcels will spend most of their journey under some form of cover.

Really, parcels are only going to be uncovered for the last step between the end-delivery vehicle and the end-customer’s door. Even if it’s pouring down, there is really minimal chance of water damage.

Technically, using plastic packaging also protects items from leaks and spills. This is, however, a very small risk. For most businesses, it’s highly unlikely to justify the continued use of plastic packaging.

Nick Mills

Latest posts by Nick Mills (see all)

- How can your business reduce packaging waste? - December 29, 2022

- Use of Plastics in Food Packaging – Know Which Types are Suitable and Safe - January 14, 2022

- Which Kind of Packaging is Right for Your Product - October 10, 2021