Household printers today make our life so much easy when it comes to office documents and classroom assignments. However, with 3D printers now becoming increasingly accessible, we are looking at a revolution that’s going to change more than just the printed word. Additive manufacturing is a specialized innovation in 3D printing technology that’s going to change what you wear, sit on, eat with and even drive to work. Let’s find out what lies ahead.

Industry Use

In October 2012, the price of additive manufacturing systems were on market which ranged from $2,000 to $500,000 and were used in industries like architecture, aerospace, defense, automotive, medical replacements, etc. General Electric utilizes high-end model to create parts for turbines. Most of these systems are utilized for rapid prototyping, prior to mass production methods are used.

The major buyer is higher education. Desktop 3D printer buys by both K-12 and universities. Libraries from all over the world also buys smaller 3D printers for educational and community access.

Consumer Use

Many projects and companies are using 3D printers for home desktop. Much of this work has been used by and targeted at Maker/DIY/enthusiast/early adopter communities, with extra ties to academic and hacker communities.

RepRap Project is one of the longest working projects in desktop class. RepRap project plans to create free and open source hardware (FOSH) 3D printer, whose complete conditions are released under GNU General Public License that is able to replicate itself by printing numerous of its own parts to make more machines. RepRaps have been able to print circuit boards and metal parts. The most admired 3D printer in the world is Prusa i3, a RepRap printer.

In addition, many Recycle Bots like the commercialized Filastruder have been developed to change waste plastic, like shampoo containers and milk jugs, in inexpensive RepRap filament.

Many recently delta robots, such as TripodMaker, have been used for 3D printing to amplify fabrication speed.

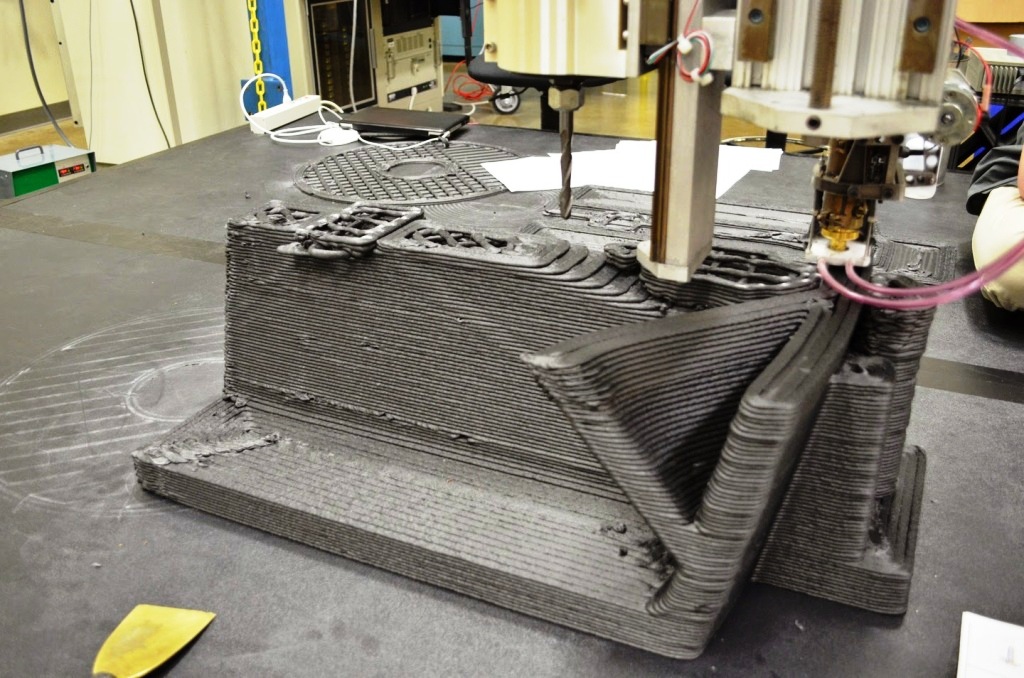

Large 3D Printers

Large 3D printers have been made for education, industrial, and demonstrative usage. Large delta-style 3D printer was developed in 2014 by SeeMeCNC. Printer is able to make the object with diameter of up to 4 feet (1.2 m) and up to 10 feet (3.0 m) in height. It also utilizes plastic pellets as raw material in spite of typical plastic filaments utilized in other 3D printers.

Another kind of large printer is Big Area Additive Manufacturing (BAAM). Main aim is to create printers which can create a large object in high speed. It can produce the object at speeds 200-500 times faster than typical 3D printers of 2014. Another BAAM machine is made by Lockheed Martin to print long objects of up to 100 feet (30 m) to be utilized in aerospace industries.

Micro Scale and Nanoscale 3D Printing

Microelectronic device fabrication process can be used to execute 3D printing of nanoscale-size objects. These printed objects are usually grown on solid substrate, like silicon wafer, to which they join after printing as they are very small and easily broken to be operated post-construction.

In one method, 3D nanostructures can be printed by actually moving dynamic stencil mask while the material deposition procedure, to some extent similar to extrusion process of traditional 3D printers. Another method improves the Photo polymerization procedure on a much smaller scale, utilizing finely-focused lasers managed by adjustable mirrors. This process has created objects with resolutions of 100 nm.

Manufacturing Applications

The applications of AM technologies are in data visualization, product development, rapid prototyping, and specialized manufacturing, architecture, industrial design, automotive, aerospace, military, construction (AEC), engineering, biotech (human tissue replacement), dental and medical industries, fashion, footwear, jewellery, education, eyewear, geographic information systems, food, etc.

With technological progress in additive manufacturing, and distribution of those development into business world, additive procedures are using into production end of producing in creative and at times unexpected ways. Parts which were initially the solitary region of subtractive process can now in few cases are made more beneficially using additive ones.

Cloud-based Additive Manufacturing

Additive manufacturing in grouping with cloud computing technologies permits decentralized and geographically independent distributed production. It refers to the service-oriented networked manufacturing model where service consumers are capable to construct parts via Platform-as-a-Service (PaaS), Infrastructure-as-a-Service (IaaS), Software-as-a-Service (SaaS) and Hardware-as-a-Service (HaaS). Few companies provide on-line 3D printing facilities to both commercial and private customers, working from 3D designs uploaded to company website.

Additional Videos

Lizare Smith

Latest posts by Lizare Smith (see all)

- 3D Printing And Rapid Prototyping Take Manufacturing To Cloud Based Model - September 3, 2016

- Prepare For Skin Care Against Tanning, Sunburns And Aging - November 14, 2015